|

Table of Summary Mechanical Engineering career How To Become Mechanical Engineer Mechanical Engineering job role Mechanical Engineering career type Mechanical Engineering career path Mechanical Engineering job responsibility Mechanical Engineering skill Machine learning Engineer scope career opportunities Mechanical Engineering scope guidance goal Certification degree course for Mechanical

Engineering Mechanical Engineering Salary in India FAQ Asked question Mechanical Engineering |

How to

Become Mechanical Engineer

Becoming a mechanical engineer involves several steps, including

education, gaining practical experience, and obtaining relevant certifications.

Here's a detailed step-by-step guide:

Understand the Field: Before

diving in, familiarize yourself with the field of mechanical engineering.

Research the roles and responsibilities of mechanical engineers, the industries

they work in, and the skills required.

Educational Requirements:

High School Education: Focus on

math and science courses such as algebra, geometry, calculus, physics, and

chemistry. Developing strong analytical and problem-solving skills during this

time will be beneficial.

Bachelor's Degree: Pursue a bachelor's

degree in mechanical engineering or a related field from an accredited

institution. Admission requirements may vary, but typically include a strong

high school GPA, SAT/ACT scores, and letters of recommendation.

Curriculum: Throughout your undergraduate

studies, you'll take courses in mechanics, thermodynamics, fluid dynamics,

materials science, CAD (Computer-Aided Design), manufacturing processes, and

engineering design. Some programs also offer concentrations or electives in

specialized areas like robotics, aerospace, or automotive engineering.

Internships and Co-op Programs: Seek out

internships or co-op programs during your undergraduate years to gain hands-on

experience and exposure to the industry.

Gain Experience and Skills:

Extracurricular Activities:

Participate in engineering clubs, competitions, or projects to further develop

your skills and network with professionals in the field.

Hands-on Projects: Engage in personal or

group projects related to mechanical engineering. This could include building

robots, designing machines, or conducting research in a specific area of

interest.

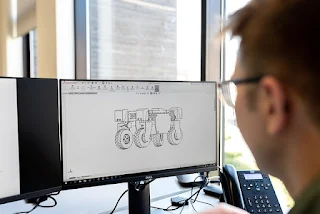

Software Proficiency:

Familiarize yourself with relevant software tools such as CAD software (e.g.,

SolidWorks, AutoCAD), simulation software (e.g., ANSYS, MATLAB), and

programming languages (e.g., Python, C++).

Obtain Relevant Certifications or Licenses:

Depending on your location and career goals, you may need to obtain

certifications or licenses to practice as a professional engineer (PE).

Requirements vary by country/state, but typically involve passing the

Fundamentals of Engineering (FE) exam and gaining relevant work experience

before taking the Professional Engineering (PE) exam.

Networking and Professional Development:

Attend industry conferences, workshops, and seminars to stay updated on

the latest advancements and trends in mechanical engineering.

Join professional organizations such as the American Society of

Mechanical Engineers (ASME) or the Institution of Mechanical Engineers (IMechE)

to connect with fellow engineers and access resources for career development.

Job Search and Career Advancement:

Utilize job search platforms, company websites, and networking

connections to explore job opportunities in your desired field or industry.

Consider pursuing advanced degrees (e.g., master's or doctoral) or

certifications to enhance your skills and advance your career in specialized

areas of mechanical engineering.

Continued Learning and Growth:

Mechanical engineering is a constantly evolving field, so stay curious

and committed to lifelong learning. Engage in professional development

activities, pursue further education, and seek out opportunities for career

advancement.

By following these steps and remaining dedicated to your education and

professional development, you can work towards becoming a successful mechanical

engineer.

Mechanical

Engineering Job Role

The job role

of a mechanical engineer encompasses a wide range of responsibilities, as

mechanical engineering is a broad field that involves the design, development,

manufacturing, testing, and maintenance of mechanical systems. Below is a

detailed list of common tasks and duties associated with mechanical engineering

roles:

Designing Mechanical Systems: Mechanical engineers design various

mechanical systems, such as engines, machines, tools, and HVAC systems. They

utilize Computer-Aided Design (CAD) software to create detailed plans and

schematics.

Analyzing and Evaluating Designs: Engineers analyze designs to ensure

they meet project requirements, performance standards, and safety regulations.

They conduct simulations and calculations to assess factors like stress,

strain, heat transfer, and fluid dynamics.

Prototyping and Testing: Mechanical engineers build prototypes of their

designs and conduct rigorous testing to assess performance, durability, and

reliability. They may use testing equipment and instrumentation to collect data

and make improvements.

Problem Solving and Troubleshooting: Mechanical engineers are often

tasked with solving complex technical problems related to mechanical systems.

They use analytical skills and knowledge of engineering principles to identify

issues and develop effective solutions.

Collaboration with Cross-Functional Teams: Mechanical engineers collaborate

with professionals from other disciplines, such as electrical engineers,

industrial designers, and project managers, to integrate mechanical systems

into larger projects and products.

Materials Selection and Specification: Engineers select appropriate

materials for mechanical components based on factors like strength, thermal

properties, and cost. They may specify materials and oversee procurement

processes.

Manufacturing Support: Mechanical engineers work closely with manufacturing teams

to ensure that designs can be produced efficiently and cost-effectively. They

may provide guidance on manufacturing processes, tooling, and quality control.

Maintenance and Repair: Mechanical engineers develop maintenance schedules and

procedures for mechanical systems to ensure optimal performance and longevity.

They may also troubleshoot issues and oversee repairs when equipment breaks

down.

Regulatory Compliance: Engineers must ensure that designs and products comply with

relevant industry standards, codes, and regulations. They stay informed about

updates and changes in regulations to maintain compliance.

Continuous Learning and Professional Development: Mechanical engineers must stay

updated on advances in technology, industry trends, and best practices. They

may attend training sessions, conferences, and workshops to enhance their

skills and knowledge.

Project Management: In many roles, mechanical engineers are responsible for

managing projects from conception to completion. This involves coordinating

tasks, setting timelines, allocating resources, and communicating progress to

stakeholders.

Documentation and Reporting: Engineers create technical documentation, including

design specifications, test reports, and user manuals. Clear and concise

documentation is essential for communicating information to colleagues,

clients, and regulatory bodies.

Research and Development: Some mechanical engineers are involved in research

and development projects, where they explore new technologies, materials, and

methods to improve mechanical systems and address emerging challenges.

Environmental and Sustainability Considerations: Engineers consider environmental

impacts and sustainability principles when designing mechanical systems. They

may explore energy-efficient solutions, recyclable materials, and waste

reduction strategies.

Customer Support and Technical Sales: In certain roles, mechanical

engineers provide technical support to customers and sales teams. They may

assist with product demonstrations, answer technical inquiries, and propose

customized solutions to meet client needs.

Mechanical

Engineering career Type

Mechanical

engineering is a broad field with numerous career paths and specializations.

Here's a detailed list of different career types for mechanical engineers:

Design Engineer: Design engineers create and develop new products,

machinery, or systems. They use CAD (Computer-Aided Design) software to design

and analyze mechanical components and systems.

Manufacturing Engineer: Manufacturing engineers focus on optimizing the production

process, ensuring efficiency, quality, and cost-effectiveness. They work on

improving manufacturing methods, processes, and equipment.

Automotive Engineer: Automotive engineers design and develop vehicles and their

components. They work on areas such as vehicle dynamics, engine design, fuel

efficiency, and safety systems.

Aerospace Engineer: Aerospace engineers design and develop aircraft,

spacecraft, and related systems. They work on aerodynamics, propulsion systems,

materials, and structures for flight vehicles.

Energy Engineer: Energy engineers work on designing and optimizing energy

systems, including renewable energy systems, HVAC (Heating, Ventilation, and

Air Conditioning) systems, and energy-efficient processes.

HVAC Engineer: HVAC engineers design heating, ventilation, and air

conditioning systems for buildings and industrial facilities. They ensure

proper climate control, indoor air quality, and energy efficiency.

Robotics Engineer: Robotics engineers design, build, and test robots and

automated systems for various applications, including manufacturing,

healthcare, and defense.

Control Systems Engineer: Control systems engineers design and implement

control systems for mechanical systems, processes, and machinery. They work on

feedback control, instrumentation, and automation.

Fluids Engineer: Fluids engineers study the behaviour of fluids (liquids and

gases) and design systems such as pipelines, pumps, and turbines. They work on

fluid dynamics, thermodynamics, and heat transfer.

Materials Engineer: Materials engineers research and develop materials for

various applications, including metals, polymers, ceramics, and composites.

They focus on material properties, performance, and durability.

Structural Engineer: Structural engineers design and analyze structures such as

buildings, bridges, and mechanical components to ensure they can withstand

loads and environmental conditions.

Renewable Energy Engineer: Renewable energy engineers work on developing and

implementing renewable energy technologies such as solar, wind, hydro, and

geothermal power systems.

Research and Development (R&D) Engineer: R&D engineers work on

innovation and product development, conducting research, prototyping, and

testing new technologies and products.

Project Engineer/Manager: Project engineers/managers oversee engineering

projects from conception to completion, managing budgets, schedules, resources,

and teams.

Quality Engineer: Quality engineers ensure that products and processes meet

quality standards and regulatory requirements. They develop and implement

quality control procedures and conduct inspections and audits.

Maintenance Engineer: Maintenance engineers are responsible for ensuring the

proper functioning and reliability of mechanical systems and equipment through

preventive maintenance, troubleshooting, and repairs.

Sales Engineer: Sales engineers combine technical knowledge with sales

skills to promote and sell mechanical products, equipment, and services to

clients.

Consulting Engineer: Consulting engineers provide expert advice and engineering

services to clients on various projects, often specializing in specific

industries or technical areas.

Naval Architect: Naval architects design and develop ships, boats, and

offshore structures. They work on ship design, hydrodynamics, stability, and

structural integrity.

Biomedical Engineer: Biomedical engineers apply engineering principles to the

design and development of medical devices, prosthetics, and healthcare

technologies.

Nuclear Engineer: Nuclear engineers work on the design, operation, and

maintenance of nuclear power plants and nuclear reactors, as well as nuclear

waste management and safety.

Environmental Engineer: Environmental engineers focus on designing solutions to

environmental problems, such as pollution control, waste management, and

sustainable development.

Academic/Researcher: Mechanical engineers can pursue careers in academia or

research institutions, conducting research, teaching, and contributing to

advancements in the field.

Entrepreneur: Some mechanical engineers start their own businesses,

either developing and selling products or providing engineering services.

Technical Writer: Technical writers specialize in creating documentation,

manuals, and instructional materials for mechanical products, equipment, and

systems.

Mechanical

Engineering Career Path

A career path for a mechanical engineer can be dynamic and diverse,

offering opportunities across various industries and specializations. Here's a

detailed breakdown of the typical career path for a mechanical engineer:

Education:

Bachelor's Degree: The journey usually begins with earning a bachelor's

degree in mechanical engineering or a related field. This undergraduate program

typically takes four years to complete and covers fundamental principles such

as mechanics, thermodynamics, materials science, and design.

Master's Degree (Optional): Some mechanical engineers choose to pursue a

master's degree for advanced specialization or to enhance career prospects.

This can take an additional one to two years of study.

Entry-Level Positions:

Upon graduation, many mechanical engineers start their careers in

entry-level positions. These roles often involve assisting senior engineers,

performing design calculations, drafting technical drawings, and conducting

research and development activities.

Common entry-level job titles include mechanical design engineer,

manufacturing engineer, quality assurance engineer, and project engineer.

Mid-Level Positions:

With several years of experience and demonstrated competency, mechanical

engineers progress to mid-level positions with increased responsibilities and

leadership opportunities.

Mid-level roles may involve overseeing projects, managing teams, and

making significant design decisions. Engineers in these positions may also be

involved in troubleshooting complex technical problems and implementing

cost-saving measures.

Job titles at this level may include senior mechanical engineer,

engineering manager, or project manager.

Specialization:

As mechanical engineers gain more experience, they often choose to

specialize in a particular area of interest within the field. Specializations

can range from aerospace and automotive engineering to HVAC (Heating,

Ventilation, and Air Conditioning), robotics, or renewable energy.

Engineers may pursue additional training, certifications, or advanced

degrees to deepen their expertise in their chosen specialization.

Advanced Positions:

For those with significant experience and expertise, opportunities for

advancement to executive or senior leadership positions become available. These

roles involve strategic planning, decision-making, and overseeing large-scale

projects or entire engineering departments.

Job titles at this level may include chief engineer, director of

engineering, or vice president of engineering.

Professional Development:

Throughout their careers, mechanical engineers are encouraged to engage

in continuous learning and professional development to stay abreast of

advancements in technology, industry trends, and best practices.

Participation in professional organizations, obtaining professional

engineering licensure, attending conferences, and pursuing further education

are common avenues for career growth and development.

Entrepreneurship and Consulting:

Some experienced mechanical engineers choose to leverage their expertise

to start their own engineering firms or consulting businesses. This path allows

them to work independently, tackle diverse projects, and have greater control

over their career trajectory.

Retirement or Transition:

As with any career, mechanical engineers may eventually choose to retire

or transition into other roles, such as teaching, mentorship, or advisory

positions within the engineering community.

Overall, the career path of a mechanical engineer offers a wide array of

opportunities for professional growth, innovation, and impact across various

industries and sectors. Continuous learning, adaptability, and a passion for

problem-solving are key traits that contribute to long-term success in this

field.

Mechanical

Engineering Job Responsibility

A mechanical engineer is involved in various aspects of designing,

developing, testing, and manufacturing mechanical systems and devices. Here's a

detailed list of job profiles for mechanical engineers:

Design Engineer:

Create detailed designs and blueprints for mechanical systems and

components using CAD software.

Conduct feasibility studies and analyze design concepts for

functionality, efficiency, and safety.

Collaborate with other engineers and professionals to optimize designs

for manufacturing and assembly.

Ensure designs comply with industry standards and regulations.

Manufacturing Engineer:

Develop manufacturing processes and procedures to produce mechanical

components efficiently and cost-effectively.

Optimize production methods to improve quality, reduce waste, and

enhance productivity.

Implement lean manufacturing principles and continuous improvement

initiatives.

Troubleshoot production issues and develop solutions to improve

manufacturing processes.

Quality Engineer:

Establish quality standards and procedures for mechanical components and

systems.

Perform inspections and quality audits to ensure compliance with

specifications and regulations.

Analyze root causes of defects and implement corrective actions to

prevent recurrence.

Work closely with suppliers and vendors to ensure quality standards are

met throughout the supply chain.

Project Engineer:

Manage engineering projects from conception to completion, including

scheduling, budgeting, and resource allocation.

Coordinate with cross-functional teams to ensure project objectives are

met within specified timelines and budget constraints.

Conduct risk assessments and implement mitigation strategies to minimize

project risks.

Communicate project status updates to stakeholders and senior

management.

Research and Development Engineer:

Conduct research to identify new technologies, materials, and

methodologies applicable to mechanical engineering.

Design and prototype innovative mechanical systems and components.

Collaborate with interdisciplinary teams to translate research findings

into practical applications.

Evaluate and test prototypes to validate performance and reliability.

HVAC Engineer:

Design heating, ventilation, and air conditioning systems for

residential, commercial, and industrial buildings.

Calculate heat load requirements, duct sizing, and equipment selection

based on building specifications.

Conduct energy efficiency assessments and recommend HVAC system

improvements.

Ensure compliance with building codes and environmental regulations.

Automotive Engineer:

Design and develop automotive components and systems, such as engines,

transmissions, and suspension systems.

Conduct performance testing and analysis using simulation software and

physical prototypes.

Collaborate with cross-functional teams to integrate new technologies

and features into vehicle designs.

Ensure compliance with safety and emissions regulations.

Aerospace Engineer:

Design and analyze aircraft structures, propulsion systems, and avionics

components.

Conduct finite element analysis (FEA) and computational fluid dynamics

(CFD) simulations to optimize aerodynamic performance.

Develop testing protocols and procedures for aerospace components and

systems.

Collaborate with regulatory agencies to obtain certification for

aircraft designs.

Energy Engineer:

Design renewable energy systems, such as wind turbines, solar panels,

and geothermal heat pumps.

Conduct feasibility studies and energy audits to identify opportunities

for energy efficiency improvements.

Develop models to predict energy consumption and optimize system

performance.

Collaborate with utilities and government agencies to implement

renewable energy projects.

Mechatronics Engineer:

Design and integrate electromechanical systems using sensors, actuators,

and control systems.

Develop automation solutions for manufacturing processes, robotics, and

autonomous vehicles.

Program PLCs (Programmable Logic Controllers) and microcontrollers to

control mechanical systems.

Conduct troubleshooting and maintenance of mechatronic systems.

Materials Engineer:

Research and develop new materials for use in mechanical applications,

such as metals, polymers, and composites.

Conduct material testing and analysis to determine mechanical properties

and performance characteristics.

Collaborate with suppliers and manufacturers to ensure materials meet

quality and performance requirements.

Investigate failure modes and develop strategies to improve material

performance and durability.

Biomedical Engineer:

Design and develop medical devices and prosthetics, such as implants,

surgical instruments, and diagnostic equipment.

Conduct biomechanical analysis and testing to ensure compatibility with

human physiology.

Collaborate with medical professionals to identify needs and

requirements for new healthcare technologies.

Ensure compliance with regulatory standards, such as FDA regulations for

medical devices.

Nuclear Engineer:

Design and analyze nuclear power plants, including reactor cores,

cooling systems, and radiation shielding.

Conduct safety assessments and develop emergency response plans for

nuclear facilities.

Collaborate with regulatory agencies to ensure compliance with nuclear

safety regulations.

Research advanced nuclear technologies, such as fusion reactors and

nuclear waste management solutions.

Marine Engineer:

Design and develop marine propulsion systems, ship structures, and

offshore platforms.

Conduct hydrodynamic analysis and stability calculations for marine

vessels.

Collaborate with naval architects and shipbuilders to optimize vessel

designs for performance and efficiency.

Ensure compliance with marine safety regulations and environmental

standards.

Instrumentation and Control Engineer:

Design and implement control systems for industrial processes and

machinery.

Program PLCs, DCS (Distributed Control Systems), and SCADA (Supervisory

Control and Data Acquisition) systems.

Conduct system integration and commissioning of instrumentation and

control systems.

Troubleshoot control system issues and implement corrective actions.

These are just a few examples of the diverse job profiles available to

mechanical engineers, showcasing the broad range of industries and applications

where their skills are highly valued.

Mechanical

Engineering Skill

Here's a comprehensive list of skills relevant to mechanical

engineering:

Technical Skills:

Proficiency in CAD (Computer-Aided Design) software such as AutoCAD,

SolidWorks, CATIA, or Pro/ENGINEER for designing mechanical components and

systems.

Understanding of engineering drawings, GD&T (Geometric Dimensioning

and Tolerancing), and drafting standards.

Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) for

analyzing structural integrity and fluid flow characteristics.

Knowledge of MATLAB or Python for numerical analysis, modeling, and

simulation.

Experience with engineering software packages like ANSYS, Abaqus, or

COMSOL for advanced analysis and simulations.

Ability to perform tolerance stack-up analysis to ensure proper fit and

function of mechanical assemblies.

Familiarity with thermodynamics, heat transfer, fluid mechanics, and

mechanical vibrations for system analysis and design.

Proficient in material selection and understanding material properties

for various applications.

Knowledge of manufacturing processes including machining, casting,

injection molding, and additive manufacturing (3D printing).

Understanding of control systems and automation for designing

mechatronic systems.

Project Management Skills:

Ability to manage projects from conception to completion, including

planning, scheduling, budgeting, and resource allocation.

Strong problem-solving skills to identify and resolve engineering

challenges efficiently.

Effective communication skills for collaborating with cross-functional

teams and presenting technical information to stakeholders.

Experience with risk assessment and mitigation strategies to ensure

project success.

Familiarity with project management tools such as Gantt charts, PERT

diagrams, and Agile methodologies.

Analytical Skills:

Strong mathematical background including calculus, differential

equations, linear algebra, and numerical methods.

Ability to analyze data and interpret results to make informed

engineering decisions.

Critical thinking and troubleshooting skills to diagnose and solve

complex mechanical problems.

Knowledge of statistical methods for experimental design, data analysis,

and quality control.

Design and Innovation Skills:

Creativity and innovation in developing new mechanical designs and

improving existing systems.

Ability to conceptualize, prototype, and test mechanical components and

systems.

Understanding of design for manufacturability (DFM) and design for

assembly (DFA) principles to optimize production processes.

Experience with rapid prototyping techniques to quickly iterate and

validate design concepts.

Familiarity with sustainable design practices to minimize environmental

impact.

Professional Skills:

Adherence to engineering ethics and standards in all aspects of work.

Continuous learning and professional development to stay updated with

the latest industry trends and technologies.

Strong attention to detail and commitment to delivering high-quality

work.

Ability to work effectively both independently and as part of a team.

Adaptability and willingness to embrace new challenges and

opportunities.

Mechanical

Engineering Career Scope Opportunities

Mechanical

engineering is a diverse field that offers a wide range of career opportunities

across various industries. Here's a detailed list of potential career paths for

mechanical engineers:

Automotive Industry: Design, development, and testing of automotive components,

systems, and vehicles. Roles may include automotive engineer, design engineer,

testing engineer, and manufacturing engineer.

Aerospace Industry: Design, development, and maintenance of aircraft,

spacecraft, and related systems. Opportunities exist in companies like Boeing,

SpaceX, NASA, and defense contractors.

Energy Sector: Work in the design and maintenance of energy systems,

including renewable energy technologies like wind turbines and solar panels, as

well as traditional energy systems such as power plants and pipelines.

Manufacturing Industry: Opportunities in manufacturing plants where mechanical

engineers design, optimize, and oversee the production of goods ranging from

consumer electronics to heavy machinery.

Robotics and Automation: Design, development, and implementation of robotic

systems and automated processes for industries such as manufacturing,

healthcare, and agriculture.

Biomedical Engineering: Designing medical devices, prosthetics, and equipment, as

well as working on healthcare-related projects such as improving surgical

techniques and developing medical imaging technologies.

Consulting: Mechanical engineers can work for consulting firms,

offering expertise in areas such as product design, process optimization, and

project management to clients across various industries.

Research and Development (R&D): Conducting research to innovate and

improve existing products or develop new technologies. This can be in academia,

government research institutions, or private companies.

Renewable Energy: Specializing in the design and development of renewable

energy systems such as wind turbines, solar panels, and hydroelectric

generators to address environmental concerns and promote sustainability.

HVAC (Heating, Ventilation, and Air Conditioning): Designing and optimizing heating,

cooling, and ventilation systems for buildings, hospitals, data centers, and

other facilities to ensure comfort, energy efficiency, and indoor air quality.

Nanotechnology: Working at the intersection of engineering, physics, and

chemistry to develop nanoscale materials and devices with applications in

electronics, medicine, and other fields.

Marine Engineering: Designing and maintaining ships, submarines, offshore

platforms, and marine equipment. Opportunities exist in shipbuilding companies,

naval architecture firms, and maritime research institutions.

Materials Science and Engineering: Researching and developing new

materials with enhanced properties for various applications, such as

lightweight alloys for aerospace, high-strength composites for automotive, and

biomaterials for medical implants.

Supply Chain Management: Applying engineering principles to optimize supply

chain processes, including inventory management, logistics, and distribution,

to improve efficiency and reduce costs.

Quality Control and Assurance: Ensuring the quality and

reliability of products through testing, inspection, and quality management

systems in industries such as manufacturing, automotive, and aerospace.

Project Management: Overseeing the planning, execution, and completion of

engineering projects, coordinating resources, managing budgets, and ensuring

deadlines are met.

Environmental Engineering: Addressing environmental challenges such as

pollution control, waste management, and sustainable development by applying

engineering principles to design and implement solutions.

Defense and Security: Working on the design and development of military vehicles,

weapons systems, surveillance equipment, and defense technologies in government

agencies or defense contractors.

Technical Sales and Marketing: Using technical expertise to

support sales efforts, demonstrate product capabilities, and communicate with

customers in industries such as manufacturing, engineering software, and

industrial equipment.

Academia and Education: Teaching and conducting research at universities or

colleges, training the next generation of engineers, and contributing to

advancements in the field through scholarly work.

Entrepreneurship: Starting your own engineering firm or tech startup to

develop innovative products or services, disrupt existing industries, and solve

complex problems.

Systems Engineering: Integrating various engineering disciplines to design and

manage complex systems, ensuring all components work together efficiently and

meet performance requirements.

Occupational Health and Safety: Ensuring workplace safety by

identifying and mitigating hazards, conducting risk assessments, and developing

safety protocols in industrial settings.

Human Factors Engineering: Designing products and systems that are

user-friendly and ergonomic, considering human capabilities and limitations to

enhance usability and safety.

Forensic Engineering: Investigating failures, accidents, and disasters to

determine their causes and prevent recurrence, providing expert testimony in

legal proceedings.

Water Resources Engineering: Designing and managing water-related infrastructure

such as dams, levees, irrigation systems, and water treatment plants to ensure

efficient use and conservation of water resources.

Urban Planning and Transportation: Contributing to the design and

development of sustainable cities and transportation systems, including public

transit, roads, bridges, and traffic management solutions.

Technical Writing and Documentation: Creating technical manuals,

specifications, and documentation for engineering projects, products, and

systems to facilitate understanding and usage.

Renovation and Restoration: Working on the preservation, renovation, and

restoration of historical buildings, monuments, and structures, ensuring they

meet modern standards while preserving their cultural and architectural

significance.

Instrumentation and Control Systems: Designing and implementing control

systems and instrumentation for processes and equipment in industries such as

manufacturing, chemical processing, and power generation.

Mechanical

Engineering Goal Guidance

Guidance for Setting Mechanical Engineering Goals:

Define Your Purpose:

Begin by clarifying your long-term objectives in the field of mechanical

engineering. This could include aspirations such as becoming a design engineer,

specializing in renewable energy systems, or leading research and development

projects.

Consider your interests, strengths, and values to align your goals with

what truly motivates you.

Set SMART Goals:

Specific: Clearly define what you want to achieve. For example, instead

of a vague goal like "improve skills," specify "master CAD

software proficiency."

Measurable: Establish criteria to quantify your progress and determine

when you've achieved your goal. This could involve completing courses, gaining

certifications, or developing a portfolio.

Achievable: Ensure your goals are realistic and feasible given your

resources, time, and current skill level.

Relevant: Align your goals with your career aspirations and the demands

of the mechanical engineering field.

Time-bound: Set deadlines to create a sense of urgency and hold yourself

accountable.

Short-Term Goals:

Break down your long-term objectives into smaller, manageable tasks.

Short-term goals should serve as stepping stones toward your ultimate vision.

Examples of short-term goals could include completing specific

coursework, participating in internships or co-op programs, or acquiring

relevant technical skills.

Continuous Learning:

Recognize that the field of mechanical engineering is constantly

evolving. Stay updated on the latest industry trends, technological

advancements, and best practices.

Allocate time for continuous learning through online courses, workshops,

conferences, and professional development opportunities.

Gain Practical Experience:

Seek hands-on experience through internships, co-op programs, research

projects, or part-time jobs in relevant industries.

Practical experience not only enhances your skill set but also provides

valuable insights into real-world engineering challenges and solutions.

Networking and Mentorship:

Build relationships with professionals in the field through networking

events, industry conferences, and online platforms like LinkedIn.

Seek out mentors who can offer guidance, advice, and support as you

navigate your career path in mechanical engineering.

Personal Development:

Don't neglect personal growth alongside your technical skills. Develop

qualities such as effective communication, problem-solving abilities,

leadership skills, and resilience.

Engage in activities that foster creativity, critical thinking, and

innovation.

Evaluate and Adapt:

Regularly assess your progress towards your goals. Reflect on what's

working well and areas where you can improve.

Be flexible and willing to adapt your goals as circumstances change or

new opportunities arise.

Celebrate Achievements:

Acknowledge and celebrate your accomplishments, whether they're big or

small. This boosts morale and reinforces your commitment to your goals.

Seek Feedback:

Solicit feedback from peers, mentors, professors, and industry

professionals. Constructive criticism can help you identify areas for

improvement and refine your goals accordingly.

Mechanical

Engineer Degree certificate course

Mechanical engineering is a field of engineering that deals with the

design, construction, and operation of machinery, structures, and systems. It's

one of the broadest and oldest branches of engineering and encompasses various

sub-disciplines such as thermodynamics, fluid mechanics, materials science,

structural analysis, and manufacturing processes. The curriculum for a

mechanical engineering degree varies somewhat from country to country, but

generally covers similar fundamental concepts and principles.

India:

In India, a Bachelor of Technology (B.Tech) or Bachelor of Engineering

(B.E) degree in Mechanical Engineering is typically a four-year undergraduate

program offered by many universities and engineering colleges across the

country. The curriculum is designed to provide students with a strong

foundation in mathematics, physics, and engineering sciences, along with

specialized courses in mechanical engineering.

The course usually includes subjects such as:

Mathematics (Calculus, Differential Equations, Linear Algebra)

Physics (Classical Mechanics, Thermodynamics, Fluid Mechanics)

Engineering Mechanics

Strength of Materials

Machine Design

Heat Transfer

Manufacturing Processes

Control Systems

Engineering Drawing and CAD/CAM

Industrial Engineering

Robotics and Automation

Project Management

Environmental Engineering

Electrical and Electronics Engineering basics

Students also undertake laboratory sessions, projects, and internships

to gain practical experience and apply theoretical knowledge to real-world

problems. Additionally, many universities offer elective courses allowing

students to specialize in areas such as automotive engineering, aerospace

engineering, renewable energy, or mechatronics.

Other Countries:

While the core concepts of mechanical engineering remain consistent

across the globe, the specific structure and focus of the degree program may

vary from one country to another. For instance:

United States: Mechanical engineering

programs in the US typically follow a similar structure to India, with a strong

emphasis on mathematics, physics, and engineering principles. Students often

have the flexibility to choose elective courses based on their interests.

United Kingdom: In the UK, mechanical

engineering degrees are often offered as Bachelor of Engineering (BEng) or

Master of Engineering (MEng) programs. The curriculum combines theoretical

study with practical applications, and students may have the opportunity to

specialize in areas such as automotive engineering, aerospace engineering, or

renewable energy.

Canada: Canadian universities offer

Bachelor of Applied Science (BASc) or Bachelor of Engineering (B.Eng) degrees

in mechanical engineering. The curriculum includes core courses in mathematics,

physics, and engineering, along with specialized courses in areas like

robotics, materials science, and fluid dynamics.

Australia: Mechanical engineering degrees

in Australia are typically offered as Bachelor of Engineering (Honours)

programs. The curriculum covers fundamental engineering principles, with

opportunities for specialization in areas such as biomedical engineering, energy

systems, or mechatronics.

Overall, regardless of the country, a degree in mechanical engineering

equips students with a strong foundation in scientific and engineering

principles, problem-solving skills, and practical experience essential for a

career in various industries including automotive, aerospace, manufacturing,

energy, and robotics.

Mechanical

Engineer Salary

salaries for mechanical engineers vary greatly depending on factors such

as location, experience, industry, and level of education. Here's a general

overview of mechanical engineer salaries in India and several other countries:

India:

Entry-level mechanical engineers in India typically earn between INR

3,00,000 to INR 6,00,000 per annum.

Mid-level engineers with around 5-10 years of experience can expect

salaries ranging from INR 6,00,000 to INR 12,00,000 per annum.

Senior mechanical engineers or those with over 10 years of experience

can earn upwards of INR 12,00,000 per annum.

United States:

Entry-level mechanical engineers in the US typically earn between

$50,000 to $70,000 per annum.

Mid-level engineers with 5-10 years of experience can expect salaries

ranging from $70,000 to $100,000 per annum.

Senior mechanical engineers or those with over 10 years of experience

can earn upwards of $100,000 per annum, sometimes exceeding $150,000 in certain

industries or locations.

United Kingdom:

Entry-level mechanical engineers in the UK typically earn between

£25,000 to £35,000 per annum.

Mid-level engineers with 5-10 years of experience can expect salaries

ranging from £35,000 to £50,000 per annum.

Senior mechanical engineers or those with over 10 years of experience

can earn upwards of £50,000 per annum.

Canada:

Entry-level mechanical engineers in Canada typically earn between CAD

50,000 to CAD 65,000 per annum.

Mid-level engineers with 5-10 years of experience can expect salaries

ranging from CAD 65,000 to CAD 85,000 per annum.

Senior mechanical engineers or those with over 10 years of experience

can earn upwards of CAD 85,000 per annum.

Australia:

Entry-level mechanical engineers in Australia typically earn between AUD

50,000 to AUD 70,000 per annum.

Mid-level engineers with 5-10 years of experience can expect salaries

ranging from AUD 70,000 to AUD 100,000 per annum.

Senior mechanical engineers or those with over 10 years of experience

can earn upwards of AUD 100,000 per annum.

These figures are approximate and can vary based on factors such as

company size, industry, geographical location, and economic conditions.

Additionally, salaries may be influenced by benefits such as bonuses,

profit-sharing, and other perks. It's always a good idea to research specific

companies and regions for more accurate salary information.